Digital Twin

Independent research firm Verdantix predicts the market for digital twins will bring transformational value to operations and real-time risk management in facilities.

A digital twin (DT) offers different sophistication levels which deliver value in an incremental and exponential way:

DT Descriptive

DT Informative

DT Predictive

DT Integrated

DT Transformative

Advanced simulation algorithms for the entire building.

Advanced predictive analysis with AI and ML algorithms.

Integration with AR/VR technology to improve immersion in interaction between digital and real elements.

Anomalous correction autonomously.

Goal

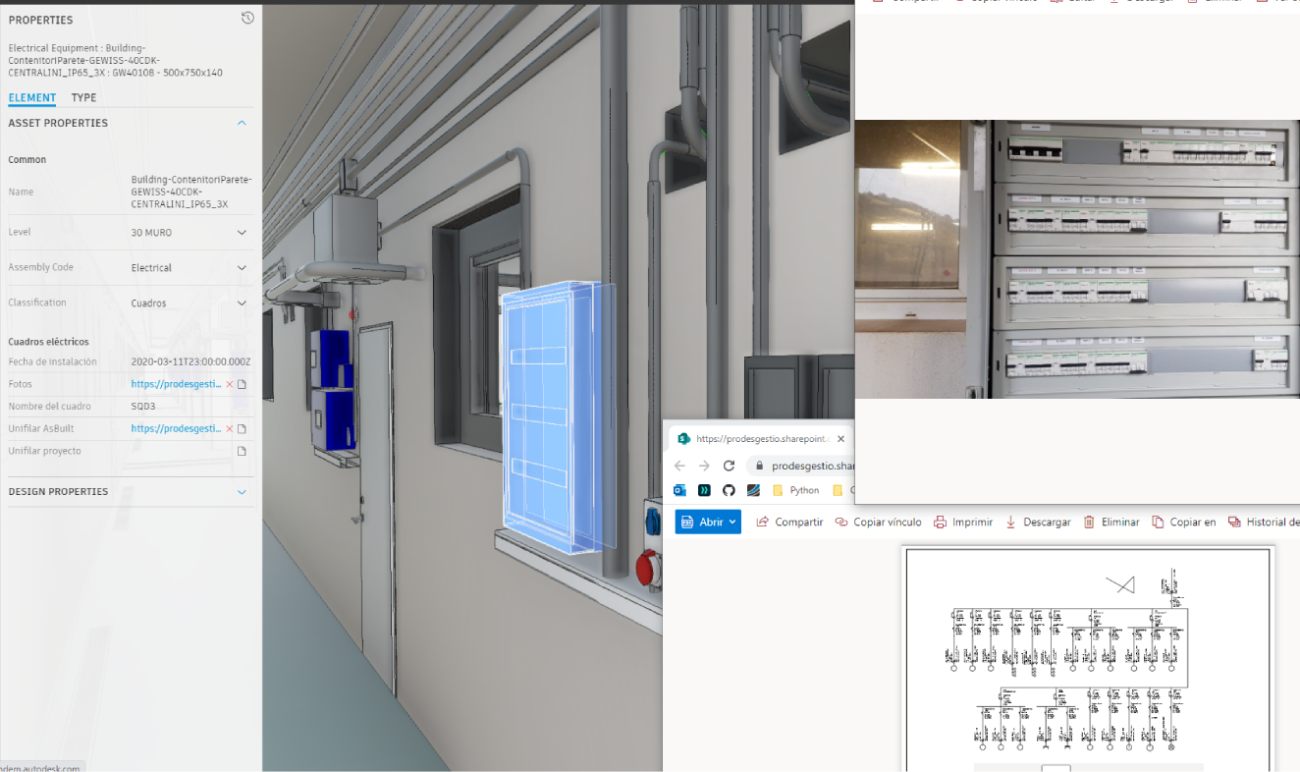

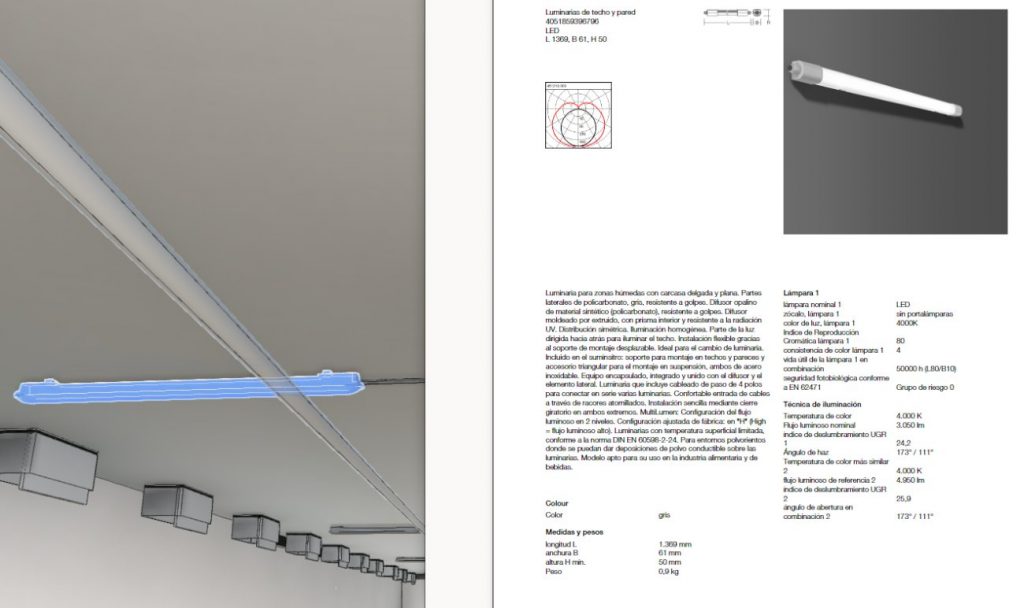

A digital twin enables new ways of interaction with a building in the sense there is a cloud 3D model which is device responsive and that gathers all information concerning every building item. Whether it is material features or system performance data it all configures a database that can be accessed in an immersive and effortless way. All this makes an easier:

- Commissioning going from design data to actual construction.

- Maintenance operations

- Facility management and operation management of the building .

What we offer

1.

Buildings with improved and longer operational efficiency

2.

A digital twin can upgrade towards predictive maintenance which delivers lower downtime and longer asset lifespan.

3.

Asset optimization in a way that underused or underperforming equipment can be identified.

4.

Simulation and stress test for a better understanding of the actual performance of the building.

5.

Lower energy, water and other basic resources consumption.

6.

Digital commissioning providing ensuring long term performance an operation.

7.

Pattern recognition to optimize equipment health and avoid downtime.

INFORMATION UPDATES